Email: evotech2023_1@163.com Tel: 86-19032448599

Home Products 3D-Scanning-Measurement Automated 3D System AutoScan-T 3D System

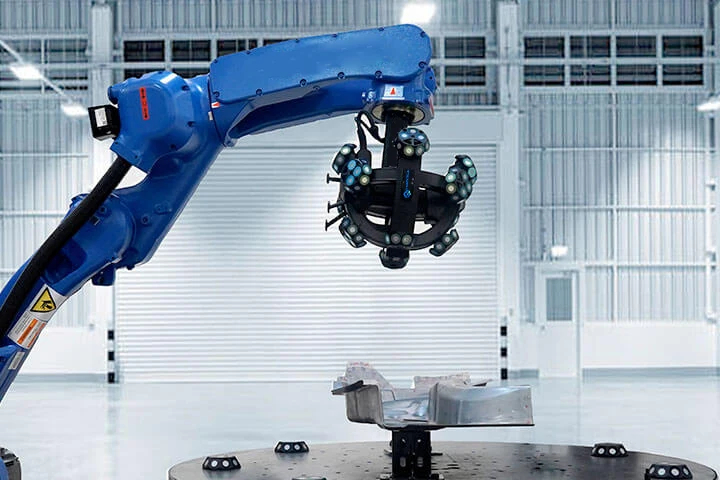

AutoScan-T automated 3D system is a new upgrade for intelligent automated inspection. It is specially designed for automated quality control in shop-floor conditions, facilitating enterprises to achieve the optimum matching between cost and efficiency.

AutoScan-T conducts non-destructive scanning without attaching markers. Its seamless connection with the production line greatly contributes to the reduction of the workload. The military-grade manufacturing quality presents strong anti-interference and high adaptation to the complex and harsh workshop environments. It can be extensively used in national defense, energy, 5G, mold manufacturing, etc., users can easily operate the system owing to one-click start, offline programming, and compatibility with 3D software.

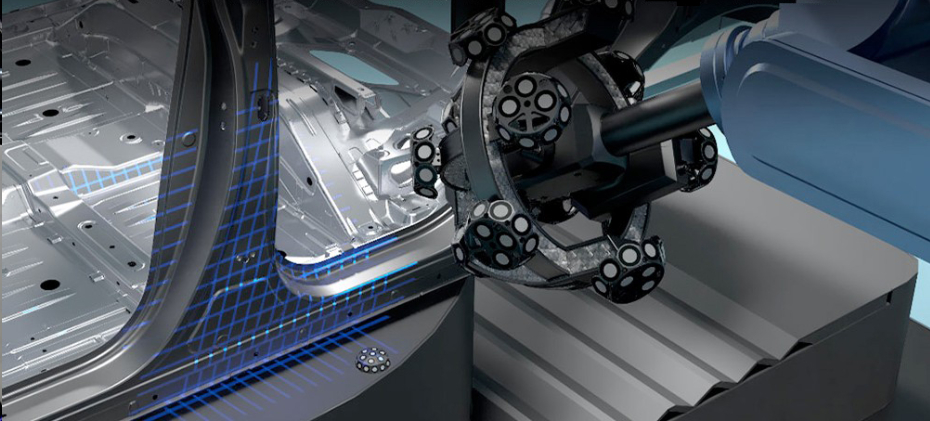

Work Seamlessly with Production Line

Based on automatic optical tracking and seamlessly integrated into the production line, it is designed for online automated inspection and enhances the iterative efficiency of the production process greatly.

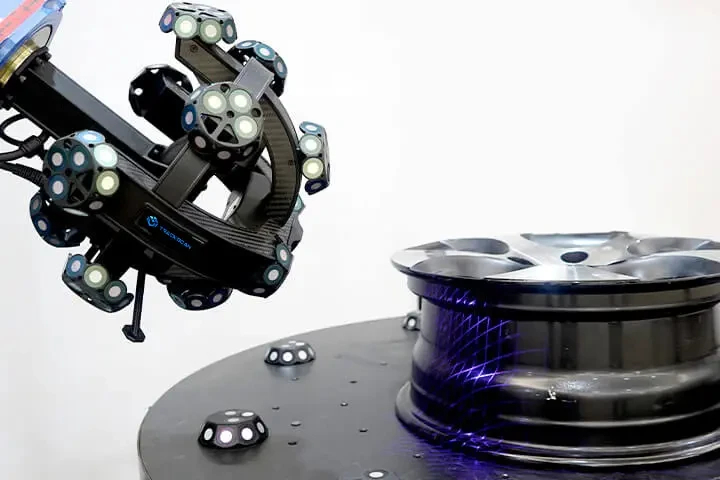

Multiple Configurations

Conjunction with the handheld 3D scanner, portable CMM, MSCAN photogrammetry system, rotary platforms, and guide rails, realize simultaneous optical tracking and scanning and personalized solutions.

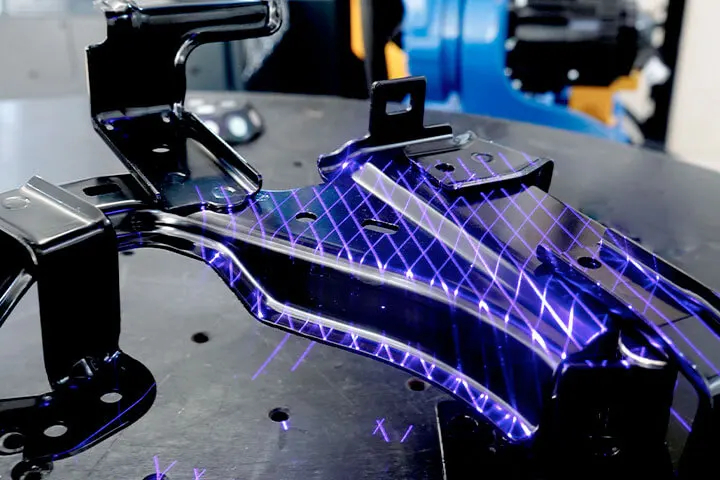

Speed up Precise Inspection

With the adoption of blue laser and synchronous tracking technologies, it reaches up to 1,900,000 measurements/s and an accuracy of 0.025 mm. Efficient and flexible automated manufacturing can be achieved without being affected by external factors.

Military-grade Quality

Being insusceptible to temperature, vibration, dust, etc., the military-grade design presents superior adaptability in harsh industrial environment.

Simple Operation

Due to One-click start, offline programming and generating automated inspection, it enables simple operation for users, regardless of their experience, to easily finish the measurement.

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.

Name: Bruce

Mobile:86-19032448599

Whatsapp:8619032448599

Email:evotech2023_1@163.com

Add:Building 1, Chengbei Lake Commercial Center, No. 1188 Chengbei Road, Yushan Town, Kunshan City, Suzhou City, Jiangsu Province