Email: evotech2023_1@163.com Tel: 86-19032448599

Home Products 3D-Scanning-Measurement Automated 3D System AM-CELL C Series Optical Automated 3D Me

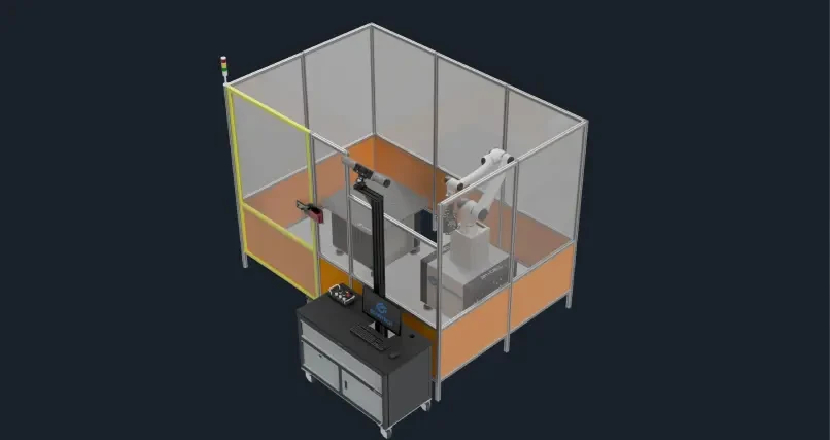

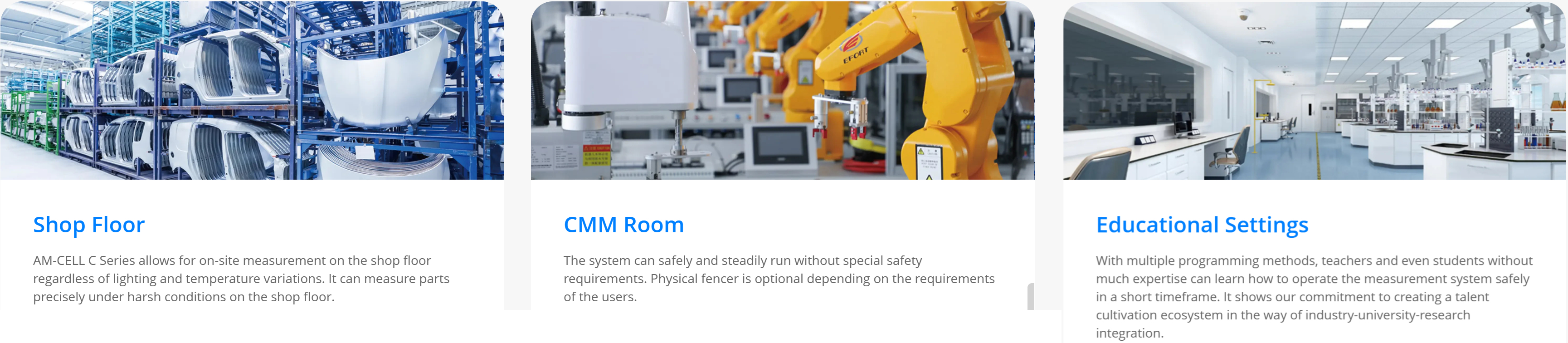

The AM-CELL C series optical automated 3D measurement system, consisting of a robot, positioner, and a tracking station, is developed for efficient and automated inspection of medium-to-large-sized parts such as stamping, injection-molded, machined sheet metal, and cast parts. Designed with innovative modular units, it enables various layouts, flexible deployment, and multiple-positioner operations.

Its standard interfaces can be connected to different external devices, allowing it to seamlessly integrate into production lines. Paired with the newly upgraded software DefinSight-AM, AM-CELL C supports efficient operations in various production environments, serving as an efficiency booster for intelligent manufacturing.

Modular Unit Design, Inspection at Fingertips

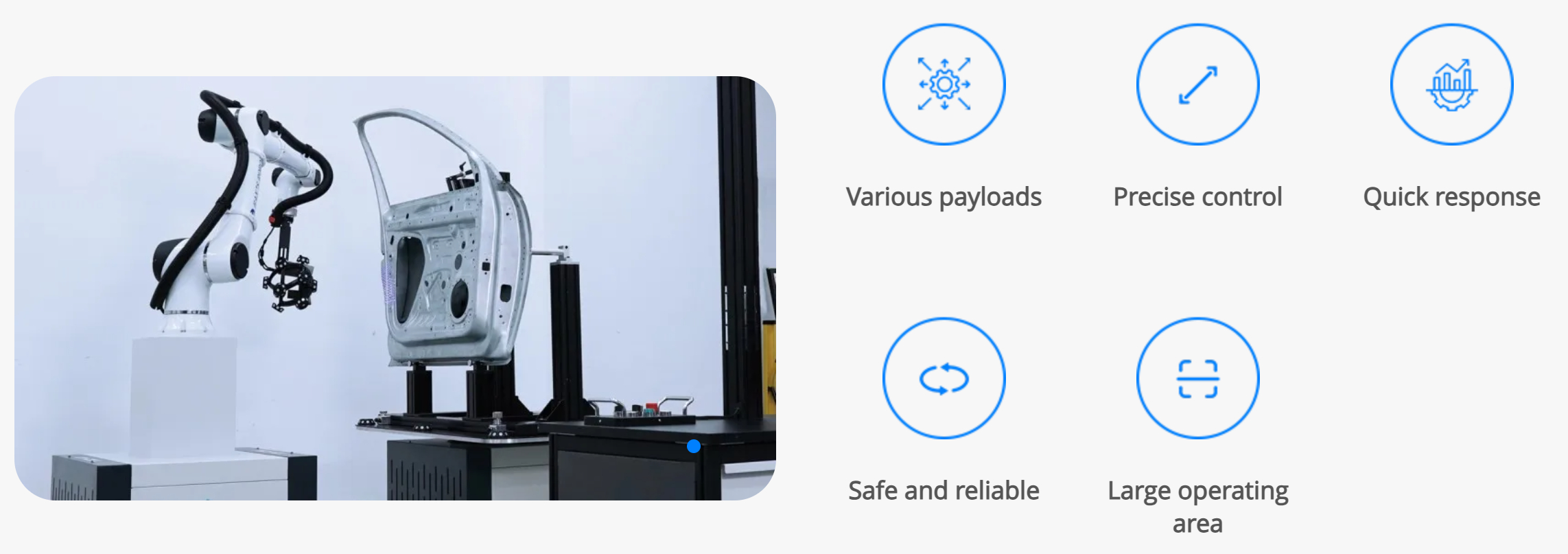

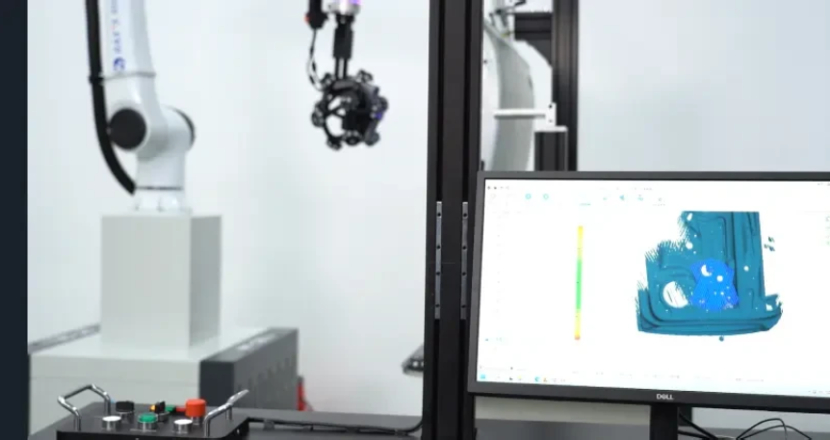

Robot Unit

When combined with i-Tracker, which has a large field-of-view, i-Probe can measure parts in a distance of up to 6 meters. The tracking distance can be extended and reach 10 meters. Its wide-area measurement enables it to measure large-sized parts with high accuracy and excellent performance.Its measurement range can be dynamicaly extended by adding more -Trackers so that it can measure large-scale objects without compromising accuracy.A special architecture comprising both robot and system controllers -Precise control -Safe and reliable

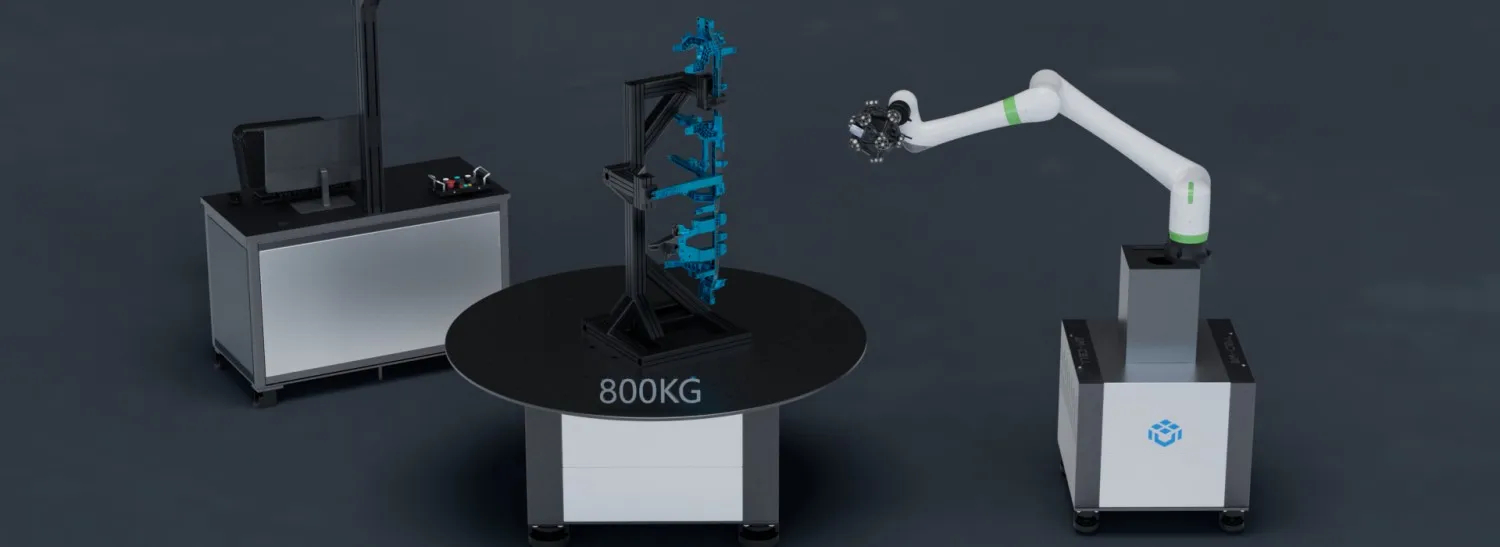

Positionertnit

High-sensitivity and in-house developed turntable -intelligent motion control system -Various paylads -Quick response and stable performance

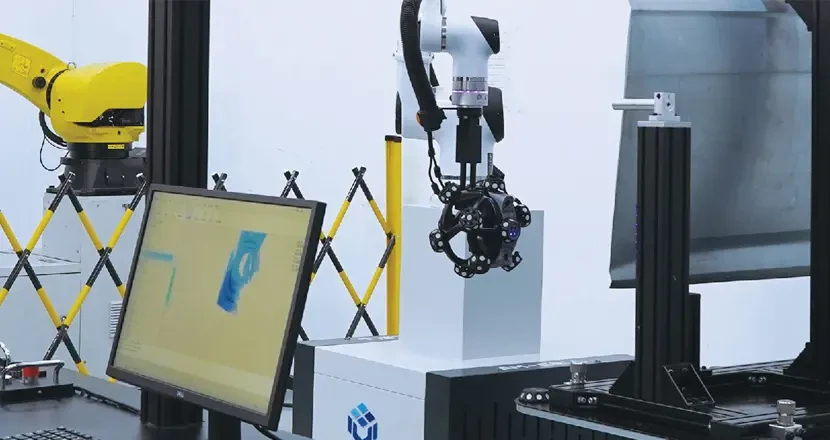

TrackStation Unit

Ergonomic structure design -Large operating area -Specially designed space for storing the measurement system

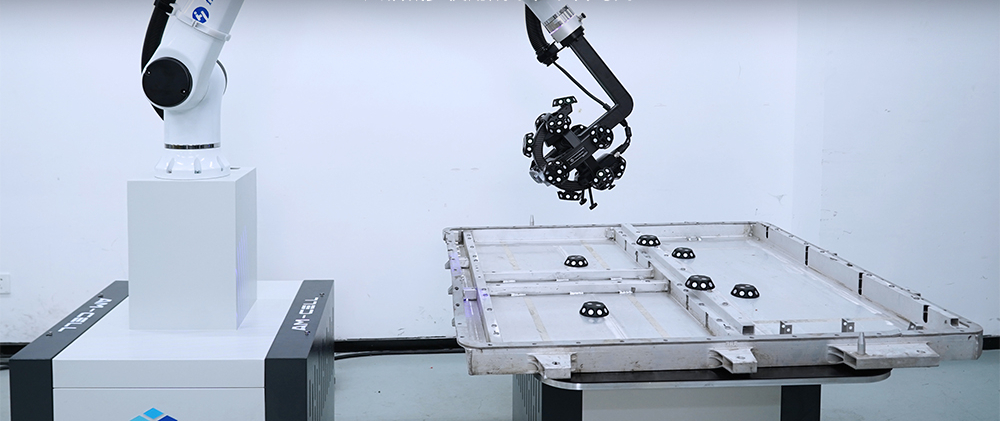

The AM-CELL C Series, compatible with SCANTECH’s full range of target-free and optical 3D measurement systems, can measure hundreds of parts automatically and stably 24 hours a day. The system delivers ultra-high measurement rate of up to 4,860,000 MPS and metrology-grade accuracy of 0.025 mm, and provides you with precise measurement results to visualize GD&T deviations.

Thanks to its sophisticated gray value measurement, the AM-CELL C Series enables automatic edge inspections and ensures precise results. Users can obtain accurate 3D data of closed features such as holes, slots, and rectangles of stamping parts and machined parts on the site.

AM-CELL C is aimed to empower the manufacturing process analysis to increase output from the source, reduce production costs, and achieve standardized quality control processes.

Users can choose different solutions with multiple positioners according to their measurement requirements, cycle time, and product categories, achieving efficient measurement with zero downtime. Thanks to the powerful software, multiple tasks can be processed at the same time. This advanced automated measurement solution enables continuous measurements, eliminating waiting or interruptions, and delivering a measurement rate 5 times faster than that of traditional CMM. Therefore, it is capable of significantly shortening production cycle and improving overall production efficiency.

AM-CELL C series is highly compatible with a wide range of long-reach cobots that come in different brands and types, especially for those with an arm span exceeding 1300 mm. The system supports plug-and-play operations without requiring additional hardware configuration, making it ideal for various industrial uses to decrease operating costs and preparation time.

Furthermore, the system offers intelligent turntables with various dimensions and payloads ranging from 200KG to 1000KG. Users can choose suitable options when inspecting parts of various weights and sizes, enjoying highly effective and adaptable automated inspection system.

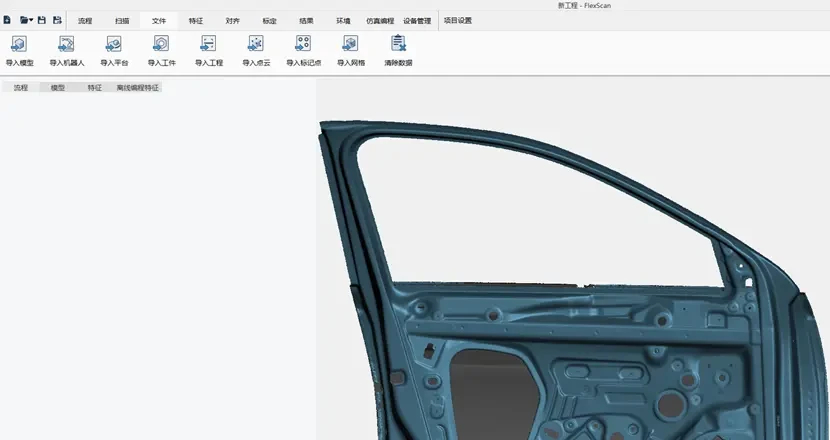

The software can be configured based on user permissions as either Engineer Mode or Operator Mode,

Engineer Mode: This mode supports off-line programming of automated measurement procedures or templates, making it convenient for engineers to maintain multiple sets of automated 3D measurement systems. Additionally, it enables engineers to trace measurement results over time and analyze statistics enhancing quality control processes for manufacturing.

Operator Mode: In Operator Mode, the software provides one-click startup, automatically invoking templates, calculations, and generating inspection reports. The operator’s access to the software is limited to only operating and reading, which ensures the safe running of programs and equipment, lowers the skill requirements, and diminishes the risks of operator errors.

Furthermore, the software supports various industrial communication protocols and device extensions, such as code reading, visual safety protection, and environmental status monitoring, which allows the entire system to be fully integrated into the industrial Internet of Things (IoT), facilitating efficient operation in lights-out factories and unmanned production environments. It allows manufacturers to monitor the evolution of batches, forecast the trend of defective products, and ensure the stability of manufacturing.

Name: Bruce

Mobile:86-19032448599

Whatsapp:8619032448599

Email:evotech2023_1@163.com

Add:Building 1, Chengbei Lake Commercial Center, No. 1188 Chengbei Road, Yushan Town, Kunshan City, Suzhou City, Jiangsu Province